Future-Proofing Connectivity: Why Businesses Are Choosing Wireless Mesh over Traditional Wi-Fi

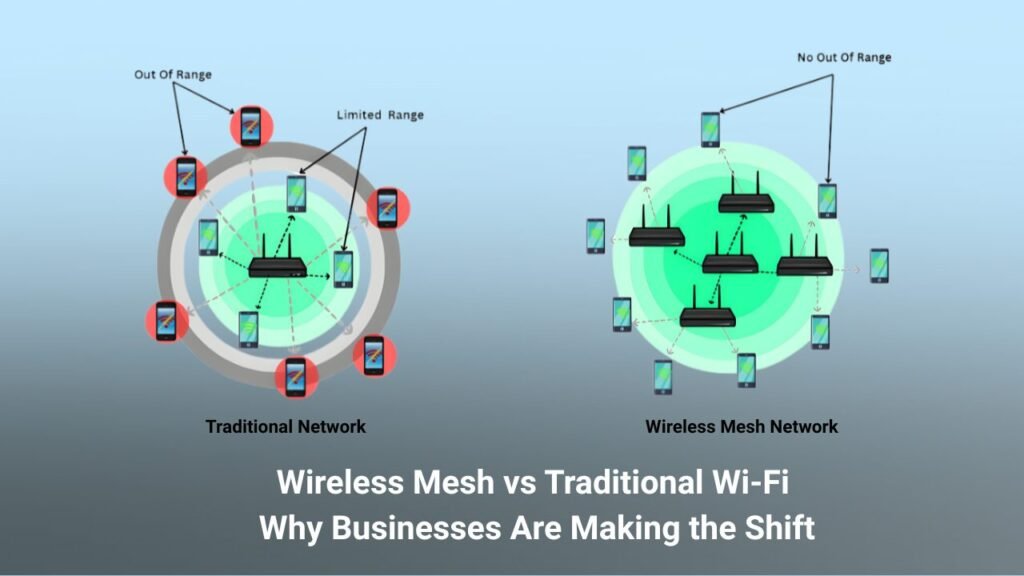

Introduction: The Need for Future-Proof Business Connectivity In today’s digital-first world, connectivity is no longer just an IT requirement – it is a business-critical foundation. From cloud applications and video conferencing to IoT devices and remote operations, modern businesses depend on fast, reliable, and scalable networks. However, many organizations still rely on traditional Wi-Fi architectures that struggle to meet growing demands. This is why businesses are increasingly shifting toward wireless mesh networks. Compared to traditional Wi-Fi, mesh networking offers greater resilience, scalability, and performance, making it a preferred choice for organizations planning long-term digital growth. This blog explores why wireless mesh is becoming the future-proof connectivity solution and how it compares to legacy Wi-Fi systems. Understanding Traditional Wi-Fi and Its Limitations How Traditional Wi-Fi Networks Work Traditional Wi-Fi typically follows a hub-and-spoke model. A central router or access point connects devices within a fixed coverage area. To expand coverage, additional access points are added, often requiring extensive cabling and manual configuration. Key Challenges of Traditional Wi-Fi for Businesses Limited scalability as networks grow Single points of failure that disrupt connectivity Performance drops with higher device density Complex maintenance and troubleshooting Higher infrastructure and cabling costs As businesses expand across offices, warehouses, campuses, or outdoor areas, these limitations become increasingly visible. What Is a Wireless Mesh Network? Core Concept of Wireless Mesh Networking A wireless mesh network consists of multiple interconnected nodes that communicate with each other. Instead of relying on a single central router, each node relays data, creating multiple pathways for traffic. How Mesh Differs from Traditional Wi-Fi No single point of failure Data dynamically reroutes if a node fails Coverage expands seamlessly by adding nodes Better performance across large and complex environments This decentralized architecture is what makes mesh networks highly reliable and adaptable. Wireless Mesh vs Traditional Wi-Fi: A Business Perspective Reliability and Network Uptime Wireless mesh networks are self-healing by design. If one node goes offline, traffic automatically reroutes through another path. Traditional Wi-Fi, on the other hand, often experiences downtime when a router or access point fails. Scalability for Growing Businesses Adding new locations, users, or devices is far easier with mesh networking. Businesses can expand coverage simply by deploying additional nodes, making it ideal for enterprises seeking the best mesh WiFi system for long-term scalability. Performance in High-Density Environments From offices and factories to campuses and public venues, wireless mesh networks handle high device density more efficiently. Traditional Wi-Fi often struggles under similar loads, leading to slow speeds and dropped connections. Cost Efficiency Over Time While initial deployment costs may be comparable, wireless mesh reduces long-term expenses by minimizing cabling, lowering maintenance needs, and reducing network downtime. Why Wireless Mesh Networks Are Future-Proof Built for IoT and Smart Infrastructure As IoT devices continue to grow, businesses need networks that can support thousands of endpoints reliably. A wireless mesh network is inherently designed for this level of connectivity. Seamless Support for Cloud and Remote Work Mesh networks deliver consistent performance across locations, making them ideal for cloud applications, hybrid work models, and real-time collaboration tools. Flexibility Across Indoor and Outdoor Environments Unlike traditional Wi-Fi, mesh networks work efficiently across warehouses, industrial sites, campuses, and outdoor areas without compromising performance. Choosing the Best Mesh WiFi System for Your Business Key Factors to Consider Coverage area and node density Security features and encryption Centralized monitoring and management Compatibility with existing infrastructure Vendor support and scalability options Industry Use Cases Enterprises with multiple offices Educational campuses Manufacturing and industrial facilities Smart cities and public safety networks Healthcare and hospitality environments Businesses across these sectors are increasingly adopting mesh solutions to stay competitive and future-ready. Conclusion: The Smart Shift Toward Wireless Mesh Networking As businesses face increasing demands for speed, reliability, and flexibility, traditional Wi-Fi is no longer enough. Wireless mesh networking offers a future-proof solution that adapts to growth, supports emerging technologies, and ensures uninterrupted connectivity. By choosing a wireless mesh network and investing in the best mesh WiFi system, organizations can build a strong digital foundation that supports innovation today and tomorrow. For businesses planning long-term success, the shift to mesh is not just an upgrade – it is a strategic move FAQs: Wireless Mesh vs Traditional Wi-Fi 01 What is the main difference between wireless mesh and traditional Wi-Fi? The main difference lies in architecture. Wireless mesh uses interconnected nodes with multiple paths, while traditional Wi-Fi relies on centralized routers and access points. 02 Is a wireless mesh network suitable for large businesses? Yes. Wireless mesh networks are ideal for large and growing businesses due to their scalability, reliability, and performance in high-density environments. 03 Does mesh WiFi provide better coverage than traditional Wi-Fi? Yes. Mesh networks eliminate dead zones by allowing nodes to communicate with each other, providing seamless and extended coverage. 04 Is wireless mesh more expensive than traditional Wi-Fi? While initial costs may be similar, wireless mesh is more cost-effective in the long run due to reduced maintenance, fewer outages, and easier scalability. 05 How do I choose the best mesh WiFi system for my organization? Consider coverage needs, security, scalability, management features, and long-term business goals when selecting the best mesh WiFi system.