WiFi 6 and Beyond: Building Smarter Industrial Wireless Networks for the Industry 4.0 Era

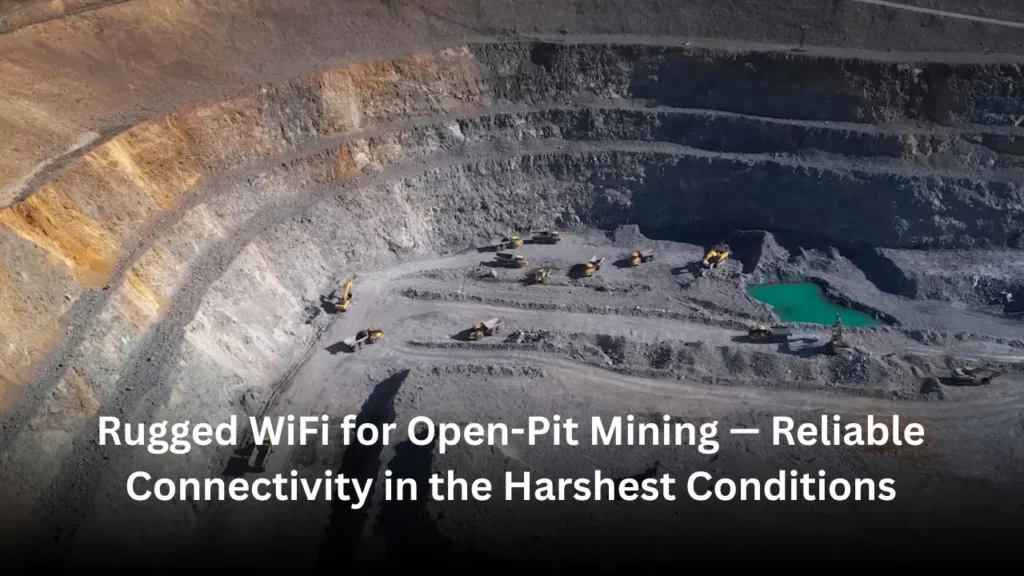

Introduction Industry 4.0 has transformed the way modern factories, industrial plants, warehouses, and large enterprises operate. Automation, robotics, predictive maintenance, and real-time analytics have become essential components of today’s production landscape. To make all this possible, industries need powerful, dependable, and scalable wireless communication infrastructure. This is where WiFi 6 for smart factories, advanced wireless mesh technologies, and next-gen connectivity solutions come into play. In this blog, we’ll explore how WiFi 6 is redefining industrial networking, the role of smart wireless mesh systems, and how industries can future-proof their network design as we move toward Industry 4.0 and beyond. What Makes WiFi 6 a Game-Changer for Industry 4.0? 1. Higher Speed & Improved Efficiency WiFi 6 offers nearly four times higher throughput compared to WiFi 5. In industrial environments where hundreds of machines, sensors, and automated vehicles communicate simultaneously, this increased speed enables real-time data flow without delays. This makes WiFi 6 ideal for wireless networking solutions for Industry 4.0 , where speed and responsiveness are crucial. 2. Designed for High-Density Environments Factories and warehouses often have thousands of connected devices-from PLCs to IoT sensors to AGVs. Traditional WiFi struggles in such congested conditions. WiFi 6 uses OFDMA and MU-MIMO technologies to handle multiple devices efficiently, ensuring continuous connectivity even during peak operations. 3. Low Latency for Automation & Robotics Industry 4.0 operations rely heavily on real-time communication. WiFi 6 brings latency down significantly, making it suitable for: Automated guided vehicles (AGVs) Collaborative robots Smart assembly lines Remote monitoring and control Low latency helps factories achieve more accurate, synchronized, and safe automation. 4. Enhanced Security for Industrial Networks Industrial networks operate in mission-critical environments where cyberattacks can disrupt production and cause high financial losses. WiFi 6 strengthens security with WPA3 encryption, protecting sensitive industrial data and ensuring secure communication across devices. Beyond WiFi 6: Why Future-Ready Industrial Wireless Networks Need More While WiFi 6 is powerful, advanced industrial environments need more than just fast WiFi. They require scalable, self-healing, and flexible wireless network architecture that can grow with their operations. This is where best mesh Wi-Fi systems and industrial-grade wireless mesh networks come in. The Role of Mesh Networks in Smart Industrial Environments 1. Self-Healing and Highly Reliable Coverage Industrial mesh systems automatically reroute data if one node fails, ensuring there’s no downtime. This reliability is vital for: Robotics Motion control Mission-critical automation 24/7 production lines 2. Scalability for Large-Scale Operations Whether it’s an enterprise campus, a manufacturing plant, or a large port, mesh networks can expand simply by adding new nodes. This makes them ideal for growing Industry 4.0 environments. 3. Improved Range & Coverage in Harsh Environments Industrial sites often struggle with obstacles like: Thick concrete Steel structures Temperature fluctuations High electromagnetic interference Mesh networks are designed to handle these challenges while providing consistent connectivity. Wireless Networking Solutions for Industry 4.0: Key Design Considerations 1. Conduct a Thorough Site Survey To build a robust WiFi 6 or mesh-based industrial wireless network, businesses must analyze: Interference sources Machinery layout Access point placement Coverage gaps Latency requirements A proper survey ensures stable and predictable performance. 2. Prioritize Redundancy and Failover Industry 4.0 systems must operate with near-zero downtime. Mesh networks with redundant paths ensure that even if one device or link fails, operations remain unaffected. 3. Build for Scalability Choose technologies that scale with your operations. WiFi 6 access points and modular mesh nodes allow businesses to expand easily whenever new automation systems or IoT devices are added. 4. Strengthen Network Security Industrial wireless networks must incorporate: WPA3 Multi-layer security Zero-trust architecture Real-time monitoring Role-based access A secure network reduces cyberattack vulnerability and ensures safe operations. WiFi 6 and Industrial IoT: A Powerful Combination As the number of sensors and connected devices in factories increases, WiFi 6 provides the bandwidth and reliability needed for seamless data flow. Industrial IoT applications that benefit most include: Predictive maintenance Digital twins RFID tracking Real-time energy monitoring Environmental sensing The combination of WiFi 6 and IoT creates a more efficient, automated, and intelligent industrial ecosystem. Best Mesh Wi-Fi System for Industrial Use Cases An industrial-grade mesh system delivers: High throughput Auto optimization One-click scalability Rugged industrial design Reliable long-range connectivity These systems are ideal for: Factories Ports Warehouses Industrial campuses Mines Oil & gas facilities With mesh networking and WiFi 6 together, businesses can build a fully unified wireless foundation for Industry 4.0. Conclusion Industry 4.0 demands high-performance, intelligent, and future-ready wireless infrastructure. WiFi 6 for smart factories brings faster speeds, improved capacity, lower latency, and stronger security-making it a major enabler of industrial automation. When combined with the best mesh Wi-Fi system and well-designed wireless networking solutions for Industry 4.0, businesses can achieve uninterrupted operations, real-time insights, and scalable digital transformation. WiFi 6 is not just an upgrade; it is a core building block for the factories of the future-where intelligent machines, people, and data seamlessly work together. FAQs 01 Why is WiFi 6 important for Industry 4.0? WiFi 6 delivers high speed, low latency, and strong security-three critical requirements for automation, robotics, and real-time industrial applications. 02 Can mesh WiFi systems work in large industrial facilities? Yes. Industrial mesh networks are designed to cover large and complex areas like warehouses, ports, and factories with reliable, self-healing connectivity. 03 How does WiFi 6 improve efficiency in smart factories? WiFi 6 supports more connected devices, reduces interference, and ensures smooth communication across IoT devices, robotics, and automation systems. 04 Is WiFi 6 secure enough for industrial environments? Absolutely. With WPA3, improved authentication, and modern encryption protocols, WiFi 6 is significantly more secure than previous generations. 05 What is the best wireless networking approach for Industry 4.0? A combination of WiFi 6 access points and industrial-grade mesh networks offers the scalability, reliability, and flexibility required for Industry 4.0 environments