Introduction

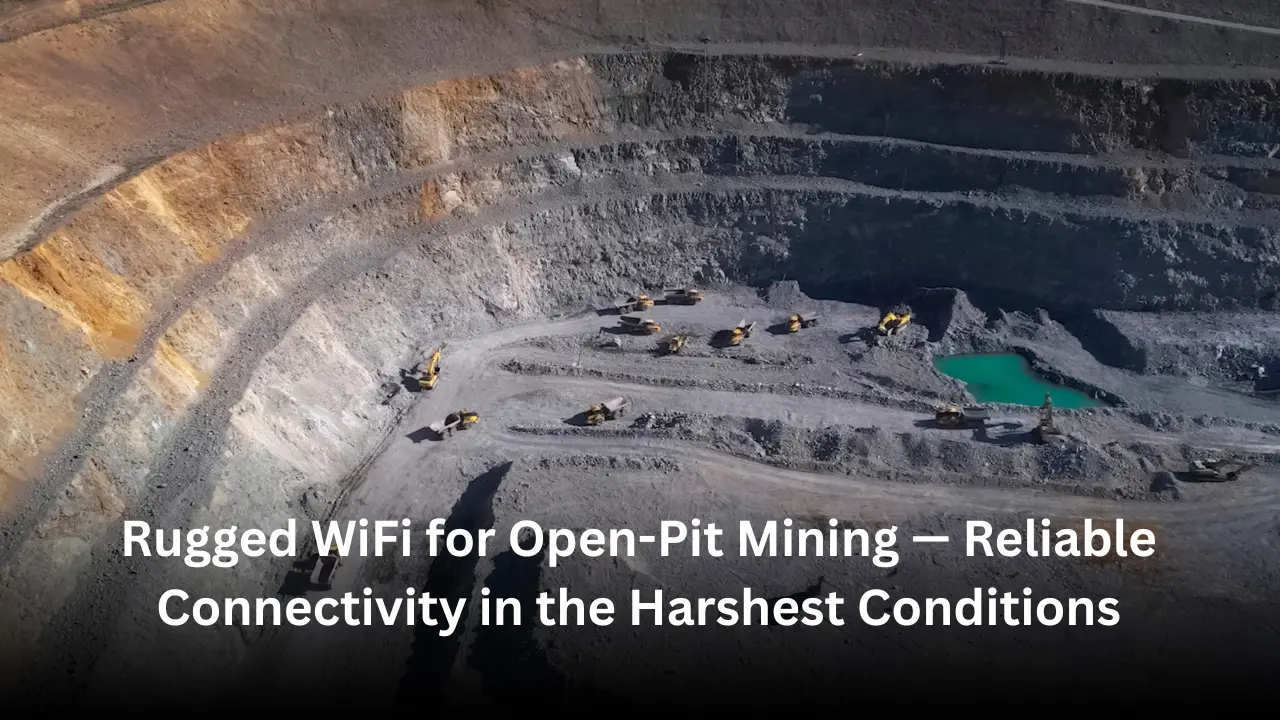

Connectivity is the backbone of modern mining operations. From real-time equipment monitoring to autonomous haul trucks, the mining industry depends on strong, uninterrupted communication networks. However, open-pit mines pose unique challenges — vast areas, harsh weather, moving equipment, and deep pits can all disrupt wireless signals.

That’s where rugged WiFi for open-pit mining and wireless networking solutions for the mining industry come into play. These advanced systems are designed to ensure seamless data flow, operational safety, and productivity — even in the world’s toughest terrains.

The Connectivity Challenge in Open-Pit Mines

Mining sites are not like traditional industrial environments. They are constantly evolving — with equipment relocation, excavation expansion, and shifting terrain. This dynamic nature makes it extremely difficult for conventional WiFi or cellular networks to maintain consistent coverage.

Key challenges include:

- Line-of-sight obstructions: Tall walls, moving trucks, and deep pits can block radio signals.

- Harsh environmental conditions: Extreme heat, dust, and vibration can damage typical network equipment.

- Large coverage areas: Mines can span kilometers, requiring a network that scales dynamically.

- Network mobility: Connectivity must move with fleets and workers as operations shift.

These challenges demand a robust and adaptive networking solution — one that’s built to survive and perform.

Rugged WiFi: Designed for Harsh Outdoor Environments

Rugged WiFi for open-pit mining is engineered specifically for outdoor and industrial conditions. Unlike consumer-grade systems, rugged WiFi uses industrial-grade access points, dust- and water-resistant enclosures, and temperature-tolerant components to ensure uptime in all conditions.

Key Features of Rugged WiFi Networks

- Weatherproof Equipment: Built to withstand rain, dust, and temperature extremes.

- Long-Range Coverage: High-gain antennas and directional radios enable communication across large sites.

- Self-Healing Wireless Mesh WiFi Networks: If one node fails, data automatically reroutes — ensuring continuous connectivity.

- Low Latency: Real-time data transmission supports autonomous operations and safety systems.

- Scalability: New access points or nodes can be easily added as the mine expands.

These characteristics make rugged WiFi the backbone of wireless networking solutions for the mining industry, powering digital transformation across remote operations.

How Wireless Mesh WiFi Networks Power Open-Pit Mining

At the heart of rugged WiFi systems lies wireless mesh WiFi technology — a decentralized approach where each node communicates with others to create a web of connectivity.

Advantages of Wireless Mesh WiFi in Mining

- Reliable Connectivity: Every access point (node) supports others, reducing downtime.

- Flexible Deployment: Ideal for constantly changing mine layouts.

- Wide Coverage: Wireless mesh WiFi networks can blanket entire mining pits and haul roads.

- Easy Scalability: Simply add more nodes to extend range without major reconfiguration.

- Real-Time Communication: Enables seamless connectivity for fleet management, IoT sensors, and safety alerts.

Solutions like these — often recognized as the best mesh WiFi systems for industrial environments — enable mining companies to maintain operational continuity and data reliability.

Building a Reliable Connectivity Framework

Designing a wireless network for open-pit mining isn’t just about installing hardware — it’s about strategic planning.

1. Conducting a Site Survey

Start with a comprehensive RF site survey to identify potential obstructions, interference sources, and coverage gaps.

2. Selecting Ruggedized Equipment

Choose routers and access points rated for industrial use — those that can tolerate vibration, moisture, and temperature extremes.

3. Implementing Redundant Wireless Mesh Links

Ensure redundancy through multi-hop wireless mesh links that automatically reroute traffic when one path is blocked or a device fails.

4. Prioritizing Security

Mining networks handle critical operational data. Use strong encryption, authentication, and firewalls to safeguard data integrity.

5. Monitoring and Maintenance

Employ centralized monitoring platforms to track performance metrics, detect issues early, and optimize network health.

The Impact of Rugged WiFi on Mining Operations

Adopting rugged WiFi for open-pit mining transforms how companies operate.

Enhanced Productivity

Seamless connectivity ensures that autonomous and remotely operated vehicles perform efficiently without manual intervention.

Improved Safety

Workers remain connected through real-time alerts and tracking, enhancing emergency response times.

Operational Visibility

Data from sensors, cameras, and control systems flows uninterrupted to centralized monitoring hubs for better decision-making.

Cost Efficiency

Reduced downtime, lower maintenance needs, and optimized equipment usage translate into significant cost savings.

Choosing the Best Wireless Mesh WiFi System for Mining

When selecting the best wireless mesh WiFi system, consider:

- Proven track record in industrial deployments

- Support for long-range and mobile nodes

- Easy integration with IoT and automation systems

- Rugged hardware with IP67 or higher ratings

- Centralized management and diagnostic tools

Some technology providers specialize in wireless networking solutions for the mining industry, offering end-to-end systems tailored to specific operational needs.

Conclusion

In the mining industry, reliable connectivity isn’t optional — it’s mission-critical. Rugged WiFi for open-pit mining provides the durability, range, and resilience needed to maintain uninterrupted communication in the harshest outdoor environments.

With wireless mesh WiFi networks and smart deployment strategies, mining companies can improve efficiency, safety, and profitability — creating a foundation for the connected mines of the future.

Frequently Asked Questions

Rugged WiFi refers to wireless systems built for extreme outdoor or industrial conditions. They use durable, weatherproof components to maintain performance despite dust, vibration, and temperature changes.

Wireless mesh WiFi provides reliable, flexible coverage across large and dynamic sites. Each node communicates with others, ensuring data flow even if one node goes offline.

They enable real-time tracking of personnel and equipment, instant alert systems, and uninterrupted communication — all of which enhance situational awareness and emergency response.

Industrial-grade materials, shockproof enclosures, IP67-rated protection, and temperature-resistant electronics make a WiFi system rugged and reliable for outdoor environments.

Look for proven systems designed specifically for large-scale industrial sites — featuring long-range coverage, scalability, and 24/7 reliability.